Insights

Sep 16, 2024

What is Industry 4.0?

The Industry in Transition

We are living in an era of constant change. Many changes in the various stages of industry are behind us. And while we have long since entered the so-called fourth industrial revolution – Industry 4.0 – it must be said that we are already in Industry 5.0. So what exactly does Industry 4.0 mean and why are we already in Industry 5.0?

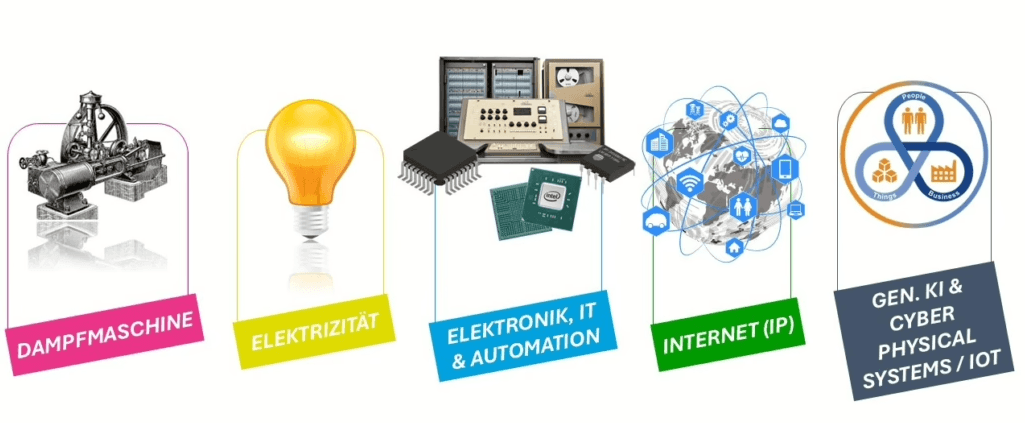

The History of Industry: From the Steam Engine to Digitization

Before we address the question of what defines Industry 4.0, it's worth taking a look back:

Industry 1.0 – The Steam Engine: The invention of the steam engine in the 18th century marked the beginning of industrialization. This mechanical energy source revolutionized production and transportation, laying the foundation for mass production.

Industry 2.0 – Electricity: With electricity came the assembly line in production halls. Particularly in the automotive industry, where Henry Ford introduced the assembly line, processes accelerated, and industrial production gained a completely new level of efficiency.

Industry 3.0 – Electronics, IT & Automation: The third revolution began in the mid-20th century. Electronic systems, computers, and programmable logic controllers (PLC) led to the automation of production. With the introduction of robots, efficiency was further enhanced.

What Does Industry 4.0 Mean?

Industry 4.0 stands for the digital transformation of industrial production, if not the entire business world. It is characterized by the networking of machines, products, and people in real time. At the center are cloud computing and constant communication and data exchange in real time through the Internet of Things (IoT). These systems enable machines to communicate with each other, exchange data in real time, and make autonomous decisions.

Here are some key elements:

Connected Systems: Machines and production facilities are connected via the internet and continuously exchange data to optimize production processes.

Real-Time Data Analysis: Sensors and other IoT devices collect enormous amounts of data, which are analyzed in real time to detect problems early and optimize processes. In the case of big data, it is a significant advantage to process these data volumes.

Autonomous Production Processes: Thanks to networking and real-time analysis, many production steps can now take place autonomously, significantly enhancing efficiency. Industry 4.0 revolutionized the way products are manufactured. Production processes are more flexible, efficient, and smarter. Yet, despite these enormous advances, we are already in Industry 5.0 and thus towards the Smart Factory.

Industry 5.0 – The Future is Now

The exponential acceleration of technological innovations means that the time spans between industrial revolutions are becoming shorter, from several centuries in the first revolution to just a few years in the fourth and fifth. The future trends are clear, and technologies are advancing. The development of robots and intelligent systems has become commonplace. While Industry 4.0 has promoted the automation and networking of production, Industry 5.0 now takes it a step further: Here, the human is once again in the foreground. With the use of artificial intelligence (AI) and advanced cyber-physical systems, as well as a more pronounced networking through the Internet of Things, an even closer cooperation between humans and machines is enabled. In Industry 5.0, it’s not just about mass production, but about customized solutions and individual needs.

Human - Machine Symbiosis in Industry 5.0

The collaboration between humans and machines is designed to complement each other's strengths. Humans bring creativity and problem-solving abilities, while machines take on repetitive tasks and data analysis. Industry 5.0 brings a wave of new value creation that reflects the growing influence of human-machine interactions, artificial intelligence, and personalized production processes.

Artificial intelligence (AI) and generative artificial intelligence (Gen AI) play a key role in Industry 5.0 as they elevate collaboration to a new level. AI enables personalized production processes and optimizes workflows in real time, while Gen AI generates innovative designs, products, and solutions. These technologies create more efficient, sustainable, and human-centered work environments where creativity and automation go hand in hand. Industry 5.0 brings the best of both human and machine worlds: efficient, automated processes combined with human creativity and flexibility. Through this, we achieve many process optimizations and create a balance between both sides. Research and innovations are increasingly oriented towards cloud computing, sustainability, and improved market opportunities. Discussion forums such as the Industry 4.0 platform develop concepts for how the economy can adhere to the framework conditions. Data protection and security naturally come to the forefront. While Industry 4.0 laid the foundation for this, Industry 5.0 creates the next generation of intelligent production and thereby also changes the economy and competitiveness.

Conclusion

Industry 4.0 has revolutionized industrial production by connecting machines, products, and people over the internet and enabling autonomous processes. But we are already looking ahead: Industry 5.0 is here and now, promising an even closer collaboration between humans and machines through AI, where individual solutions and tailored products play a central role. Companies that prepare for this revolution today secure crucial competitive advantages for the future. The future belongs to Industry 5.0 – a world where humans and machines work hand in hand to make production even more efficient and flexible.